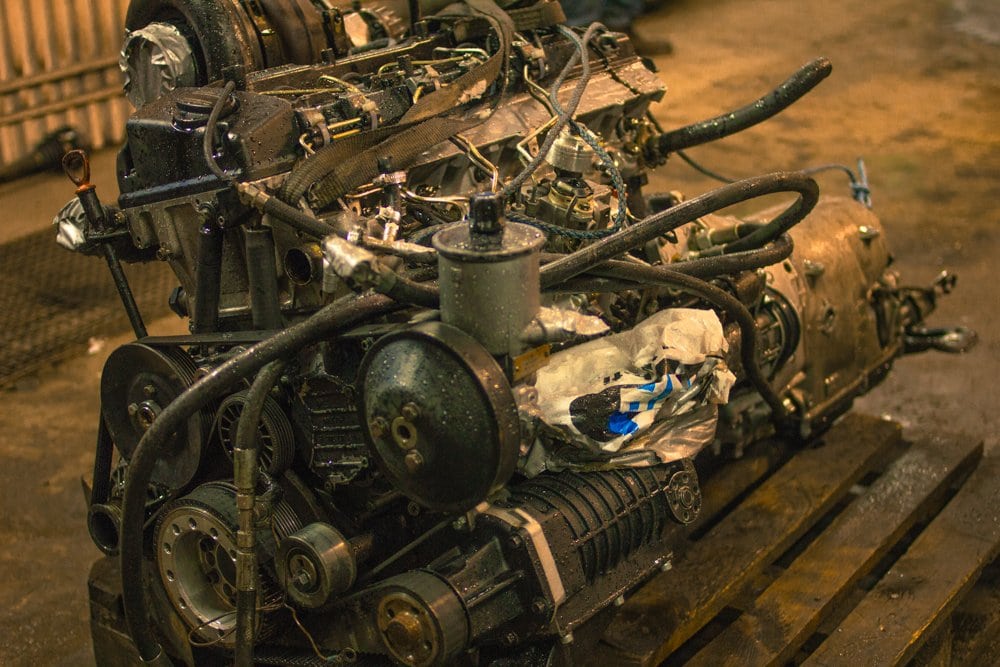

I doubt too many out there have tried putting an om606 equipped with a Holset HX52, a eaton MP90 and last but not least a e55 AMG automatic gearbox in a w203. As we started the fitting I was quite sure we would not be able to close the hood afterwards but I was wrong.

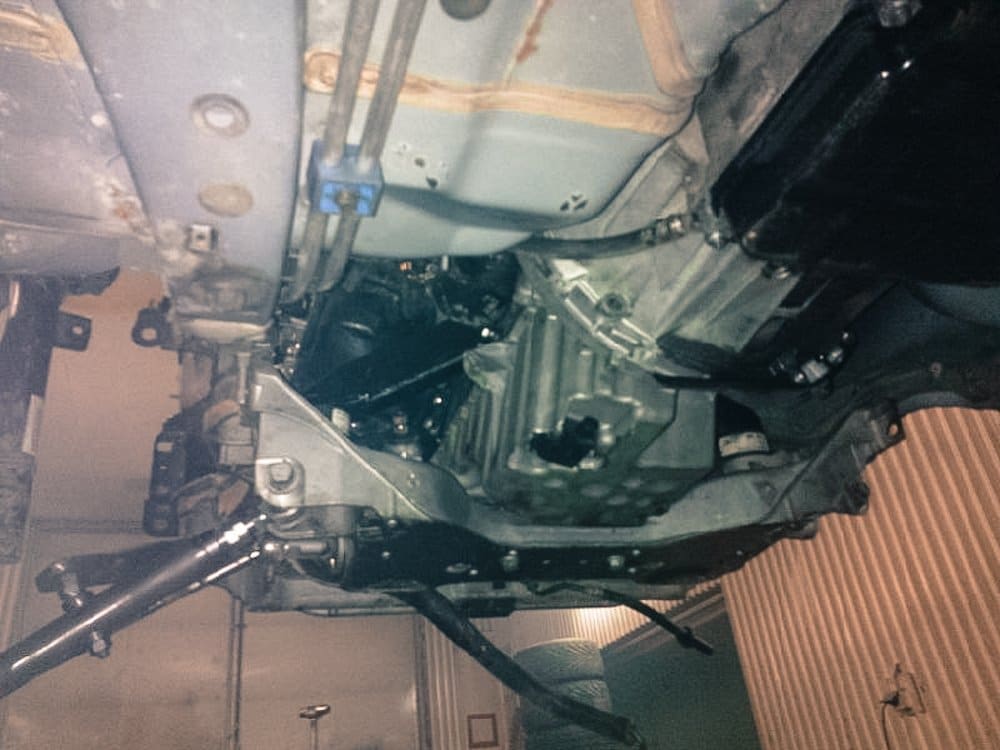

The whole fitting went quite fast and we started out simply but detaching the intake for the compressor and some hoses after which we simply dropped down the engine into the bay without cushions and POW, after a “small” cut in the hood for the turbocharger, the engine would fit perfectly into the engine bay.

I could not believe it would fit that easily, and also with a lot of space under the hood, more than in the w123. Afterwards the guys got some shiny new cushions for the engine and the gearbox. When the engine was in place with gearbox mounts and all the next few things were making a new downpipe since it’s a very tight engine bay, also some new piping for the supercharger intake and oil cooling was made.

There was also room for this oversized Chinese top quality intercooler in the front which is fitted and ready to start cooling some 3,5 bars (about 50 psi) of boost. Now what clamps would take this kind of pressure? Please suggest some in the comments…

Custom V-band clamps with an O-ring?

http://www.treadstoneperformance.com/view.phtml?f_cat=Clamps%3A+T-bolt+Clamps

and keep on the great work!

What clamps? Adel Wiggins clamps of course.

Those do not look too bad… May have to consider (:

And if the price is too shocking, these knock-offs seem to do the trick without bigger problems: http://www.ebay.com/itm/ALUMINUM-PEGASUS-CLAMSHELL-CLAMP-3-5-Clamp-Purple-NEW-/160484863631

Shoot, so that’s that one susspoep.

Wiggins or Hydraflow Clamps is the only option!

Clamps are for water hoses. Thread the fittings for both the charger and the cooler.

http://www.dieselpowermag.com/features/1010dp_2000_hp_chevy_hd_tube_chassis_sled_puller/photo_10.html

haha, that’s actually not a bad idea (:

From what I’ve seen, blowing silicon hoses off their fittings is one of the most common failures for performance diesel engines due to the high boost. I would personally do this for peace of mind. Maybe even a pearl of TIG weld on each side to make sure they don’t unthread..

blew my hoses of on my om606, 3.5bar, double clamps, and a welded ring at the end to give something for the clamps to hold against.

changed those for something more serious later on.

Threaded fittings just don’t give the pipes enough room to flex an there will propably soon be problems with cracking boost piping in this kind of rough use. With adel wiggins fittings there is a little bit of flex in the joints so engine vibrations wouldn’t cause problems in the long run. This is why wiggins connections are used in many aerospace applications too.

Wiggins liittimillä pysyi kasassa Any-10 diesel pickuppi 7 baarin ahdoilla..

Siinä oli Hx-82, pro-52 sekä Eaton M112

Kuulostaa oikein hyvältä tuo

What all did you do to run both turbo and supercharger? Been trying to figure out how to do it on my 190e that is currently a 3.0 inline 6 (m103) gas motor thats turbo charged.

THis is crazy. I just bought an E55 and Im loving it.